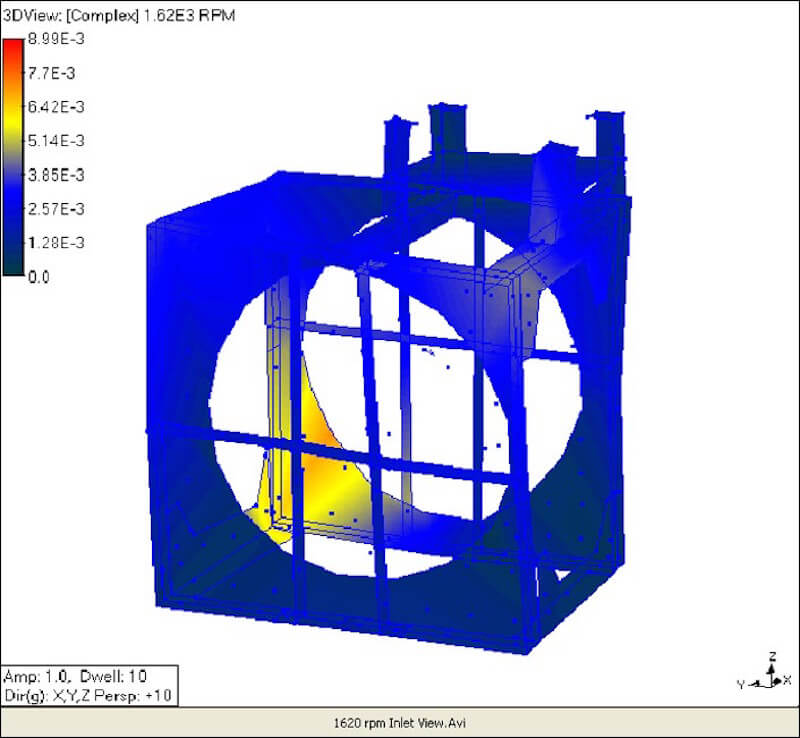

Modal testing is the process of characterizing of the ODS (Operational Deflection Shapes) of a vibrating structure. The bump or impact test became the standard for identifying resonant behavior in fan rotors. When the rotor was struck, the resonant frequency could be easily determined by a vibration analyzer equipped with an FFT (Fast Fourier Transform) processor. As the technique developed, the impacts became instrumented and the vibration levels at various points could be measured and mapped using vibration sensors (for magnitude) and oscilloscopes (for relative movement to other panels) to develop the ODS with much less equipment and labor than required by the shaker. If necessary, stress data could be made available when strain gauges were applied at locations of maximum deflection during the modal test. Stain can also be investigated with FFT processing to identify the magnitude of panel deflection present at a particular resonant frequency.

Modal testing is an advanced tool for solving rotor problems before they occur. It can also be used to investigate failures that have taken a long time to develop in the field, like fatigue cracking in a variable speed drive fan or cracking due to low-cycle fatigueThere are different types of testing that are completed using modal analysis software. By analyzing performance under different operating conditions, fans can be tested to be sure they meet the system requirements. Results can also be correlated with finite element analysis.

Products Quick Search

or